The Heye rotor mechanism has been widely adopted by the international hollow glass community, even by customers not operating the German company’s advanced IS machines.

It delivers superior thermal homogeneity and top weight consistency. The rotating movement of the rotor segments provides good thermal homogeneity of the glass melt, the equipment’s proven design guaranteeing reliable functionality and a long lifetime. Retrofit installations are possible.

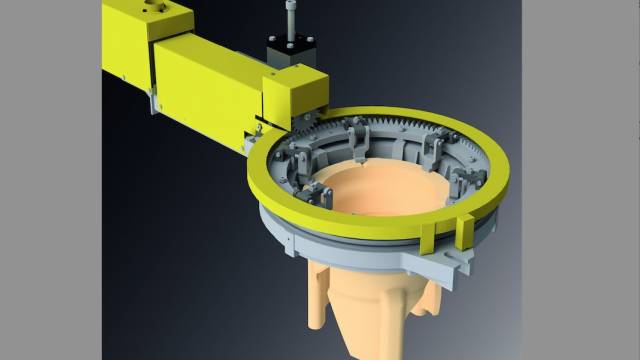

The Heye rotor mechanism is mounted at the forehearth/feeder channel. By a rotating movement of the toothed ring, three paddles provide a stirring movement in the glass melt and thereby, keep it homogenous. Unlike traditional designs that employ rotating tubes, this innovative mechanism guarantees very high thermal homogeneity. The movement generated is deflected at the bevel wheel by 90o (from horizontal to radial), so that the sprocket executes a rotating movement. The servo motor motion is controlled by Heye Simotion® Servodrive, based on the future-proof multi axis Simotion® drive system from Siemens. Excellent reliability of electronic components in combination with the application of a compact servo motor with robust resolver guarantees reliable, non-stop operation.

All movable parts are located behind an easily demountable safety housing. The rotor mechanism’s drive is torque-controlled and if blockages occur, the system stops.

Proven benefits of the rotor mechanism include good thermal homogeneity, high weight consistency, variable speeds, the ability to change the direction of rotation, the provision of a high mechanical equipment lifetime, the uniform rotation of rotor segments, height adjustment and complete housing of mechanical components. A detailed 3D simulation, showing this equipment’s advantages can be found on the Heye website www.heye-international.com.