AMETEK Surface Vision, the leading automated surface inspection partner for fast and accurate materials checking, has developed its surface inspection systems for glass fibre production.

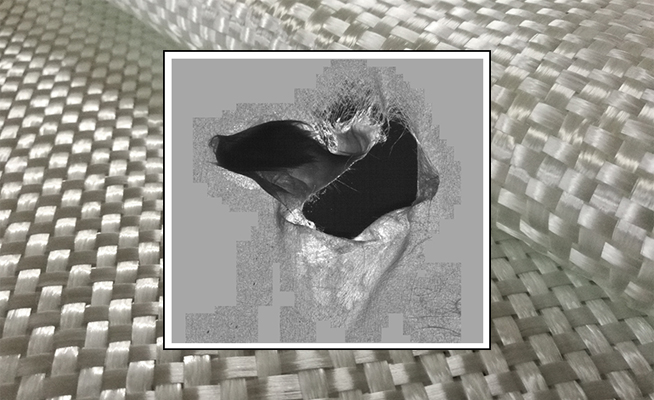

Glass fibre is a synthetic material consisting of numerous, extremely fine fibres of glass. It is a unique industrial textile material, strong and versatile for a range of applications including infrastructure, building and construction, pipes and tanks, oil, gas, chemical and transportation.

Also known as fibreglass, glass fibre and the use of glass fibre mats are growing in a wide range of applications, which has increased the need for accurate, automated inspection. The volume of wet-laid non-woven materials for construction interiors is continuing to grow alongside the demand for high-quality construction materials.

These markets expect products with perfect fibre formation. AMETEK Surface Vision uses its SmartView web inspection and SmartAdvisor web monitoring systems along with SmartSync, creating a unified inspection platform to ensure high-quality results in the production process.

This total vision integration combines the power of advanced SmartView classification with the flexible, multi-position camera technology of SmartAdvisor.

As a result, the operator can rapidly determine the root cause of any defects and take the necessary corrective action. An integrated fault map provides an accurate process quality overview, while classified defects are synchronized with the associated video files from upstream cameras. An integrated database provides comprehensive reporting for all visual anomalies.

Volker Koelmel, Global Manager of Plastic, Nonwovens & Paper, said, “Defect-free glass fibres are essential in a growing range of applications. Our proven SmartView and SmartAdvisor systems provide manufacturers of glass fibre non-woven materials with the assurance they need that defects will be identified during the production process, leading to a high-quality product and a reduction in customer claims.”

Volker Koelmel, Global Manager of Plastic, Nonwovens & Paper, said, “Defect-free glass fibres are essential in a growing range of applications. Our proven SmartView and SmartAdvisor systems provide manufacturers of glass fibre non-woven materials with the assurance they need that defects will be identified during the production process, leading to a high-quality product and a reduction in customer claims.”