The requirements for windows and glass constructions are continuously increasing due to legal and energy-related requirements – and resulting in ever shorter innovation cycles in the industry. At the FENSTERBAU FRONTALE 2020 trade show in Nuremberg, SWISSPACER is presenting a new set of applications for the SWISSPACER Air, which have been developed together with VEKA, the specialist in window profiles.

If pressure differences occur in the insulating glass in windows due to temperature differences or differences in altitude between the place of manufacturing and the point of use, the SWISSPACER Air steps in to equalise the pressure. Now, together with VEKA, SWISSPACER has now been able to expand the possible uses of the innovative component: sound insulation, heat insulation and sun protection can be improved simply by using the SWISSPACER Air.

If pressure differences occur in the insulating glass in windows due to temperature differences or differences in altitude between the place of manufacturing and the point of use, the SWISSPACER Air steps in to equalise the pressure. Now, together with VEKA, SWISSPACER has now been able to expand the possible uses of the innovative component: sound insulation, heat insulation and sun protection can be improved simply by using the SWISSPACER Air.

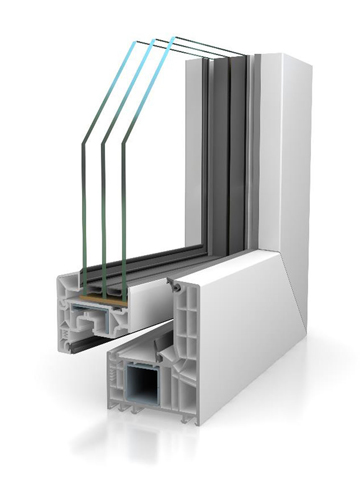

The use of the component can lead to very large spaces between the panes of glass, without the risk of damage caused by climatic stresses. This results in a large number of new possibilities for system configurations.

The PVC profile system VEKA ARTLINE 82 can hold insulation glass that is up to 60mm thick and is therefore particularly suitable for new applications with SWISSPACER Air – without compromising the performance of the windows and the comfort of those inside. Thus, large window doors with built-in blinds with pressure-equalised quadruple glazing were successfully tested at VEKA for their resistance to driving rain, wind loads and different climates. At the Rosenheim Institute for Window Technology (IFT), the sound reduction indexes of different pressure-equalised triple and quadruple glazing units were tested and evaluated.

Improved sound insulation in window manufacturing

Improved sound insulation in window manufacturing

Sound insulation is among the most important requirements for windows. This is where VEKA sees massive added value when using the SWISSPACER Air: thanks to the increased space between the panes, the noise perceived in the building can be reduced by approximately 20 percent – with an otherwise equivalent glass construction. The sound reduction index of the insulating glass is improved by up to 3dB.

A larger cavity between the panes with the SWISSPACER Air has further benefits for window fabricators. With constant sound and thermal insulation, the use of thinner glass is possible, which leads to a lower weight, which in turn is easier on the window fittings and makes them easier to use. In other cases, the costly sound-insulating interlayer in the laminated safety glass can be dispensed with. For example, a fabricator has more options for how to optimally implement customer requirements.

Ideal for shading systems in the cavity between the panes

Other constructions which require a large distance between the panes can also benefit from SWISSPACER Air. “Components such as external shading are pushed to their limits due to increasingly common extreme weather conditions and the costs of cleaning them are considerable,” explained Michael Koch of VEKA. “With the SWISSPACER Air, shading systems can be implemented more easily and safely in the cavity between the panes. When put into operation, SWISSPACER Air ensures that the glass does not bulge out or bend in even when facing severe climatic stresses, which can interfere with the freedom of movement of the built-in blinds. The big advantage: triple and quadruple designs with interior shading systems are possible and at the same time fulfil the highest demands on sound insulation and heat insulation – a system solution with similar performance characteristics to a composite window.”

These examples show that the SWISSPACER Air is much more than a pressure equalisation component. The innovative component extends the possible strategies for fabricators to meet the individual needs of their customers efficiently.

Visit us at FENSTERBAU FRONTALE in Hall 7A, booth 214 and see our new solution for yourself on site.

For more information, visit www.swisspacer.com.