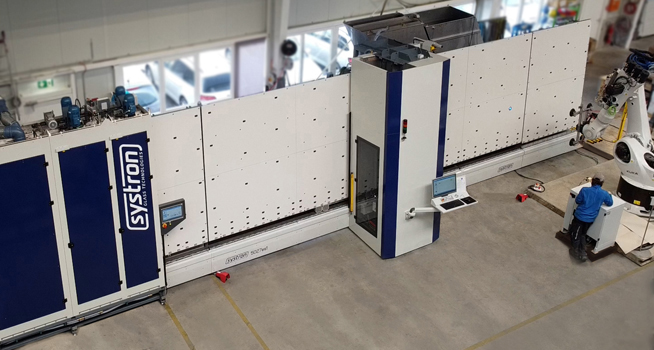

The systron esX is a high-speed seaming and grinding machine with diamond peripheral tools, which can be equipped with one or two processing spindles. It constantly follows the edge of each piece of glass to ensure preparation for reliable tempering.

systron CEO, Franz Schachner, explained, “Machine development was started in mid-2017, meanwhile some customers, such as the Glas Trösch Group or Glas Gasperlmair, are already using several systron seaming machines and are really very satisfied.”

Sophisticated design for outstanding longevity

Thanks to the simple and carefully designed construction, the esX is an exceptionally reliable and stable seaming and grinding machine.

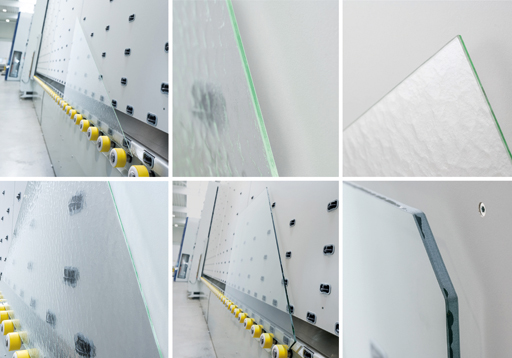

The technical parts such as motors, sensors or guide rails are placed in the dry zone. The grinding spindle is well insulated and therefore extremely water-resistant in the wet area. To ensure exact and constant height, length and thickness measurements, servo systems are used for measuring all aspects of the glass. The patented water cushion ensures tool cooling over the full circumference and prevents vibrations caused by the grinding process. It also follows the glass surface without mechanical contact, allowing for optimal processing of coated & low-E glass.

The compact construction allows for quick and easy replacement of existing seaming machines. As an option, systron can provide an integrated water purification system for space saving and easy accessibility.

Easy handling

The esX is a “passive” edge following machine since there is no activation system such as sensors initiating a process. Due to the spindle’s floating bearing, it follows the edge passively, completely and constantly. Corner dubbing avoids sharp corners and is carried out fully automatically at full speed without loss of cycle time.

Seaming and grinding without tool change

At the push of a button or fully automatically with data control, the esX can both arris and grind the glass in one process without changing tools. The same tool package can be used for glass thicknesses from 4 to 19 millimetres. Insulating glass manufacturers typically use the grinding function for large IG units often requiring a ground edge due for better stability.

Performance and sizes

Depending on the area of application, the esX can be equipped with one or two processing spindles. The cycle time difference is about 4 seconds.

Seaming cycle time including handling:

• es1: 1m/1m/8mm in 21 seconds

• es2: 1m/1m/8mm in 17 seconds

With a minimum glass size of 350 by 200 millimetres and the 3 standard machine sizes 3525, 5027 and 6033, glass up to 6 metre lengths and 3.3 metre heights can be processed, including shapes.

The systron seaming and grinding machine is typically placed in front of the tempering furnace or in line with an insulating glass unit.