Thermoseal Group is continuing to expand and now, according to Sales Director, Mark Hickox, “ … supplies over 50% of the UK spacer market and this percentage is increasing on continual basis …”.

Thermoseal Group, the UK’s leading manufacturer of warm edge spacer systems and bespoke accessories, announces further manufacturing expansion to meet the requirements of a continued increase in demand for Thermobar and Thermoflex warm edge spacers and accessories.

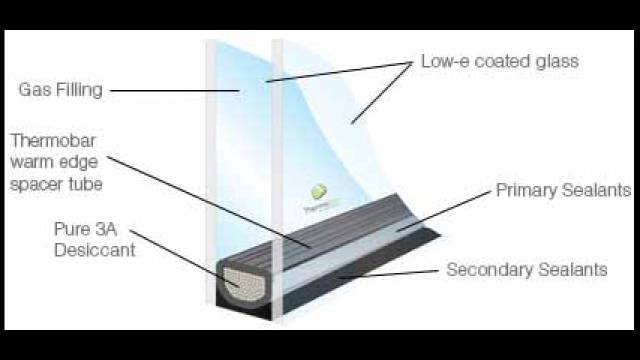

The Group’s Sales Director, Mark Hickox, discusses the company’s growth: “We now supply over 50% of the UK spacer market and this percentage is increasing on continual basis now that Thermobar is proven as the most thermally efficient spacer system with a Bundesverband Flachglass (BF) data sheet value of 0.14W/mK. Thermobar has also proven to be the preferred product for our customers to manufacture with due to its many advantages in production of insulated glass (IG) sealed units.

“Thermoflex sales are up by over a thousand percent and demand for this product is seeing continual growth as customers try the product and see its advantages in production. We also have an IFT Rosenheim thermal conductivity report issued stating that Thermoflex has been tested and proven with a thermal efficiency of 0.14W/mK. A BF data sheet will follow shortly.

“This now means that it is proven that we supply the most thermally efficient warm edge spacer tube AND foam system which, according to BFRC substitution rules, can be substituted within existing Window Energy Rating simulations for any other spacer tube system or any other foam system.

“Thermobar and Thermoflex warm edge spacers have been subject to our rigorous in-house testing facilities before they are submitted for external testing. Both products have passed relevant EN1279 tests and have also been tested to many other international standards. They are now both proving to be of interest to the international market which has compounded the growth in demand for the products and contributed towards the growth of our manufacturing facilities.

“We have invested massively in our innovation centre and EN1279 test facilities to ensure that we understand the conditions within a glazing unit and how each component performs within the lifetime of the unit. This helps us to ensure that the components we manufacture and supply are second-to-none.

“Our recent investment in three additional Thermobar production lines and an additional Thermoflex line is testament to our confidence in our products. We know that we have industry-leading products and market demand both in the UK and through export customers. We have just booked to exhibit at Vitrum exhibition in Milan and GlassBuild Atlanta later this year. We also have new warm edge products in the pipeline that we look forward to introducing to the market.”