Thermoseal has announced that it has increased its production rate of its new warm edge spacer – Thermoflex – and now has ample stocks of all sizes of Thermoflex, aiming to supply customers within three days or less via its own fleet of vehicles.

Thermoseal Group, the UK’s leading manufacturer of warm edge spacers and supplier of over 1,500 components to insulated glass sealed unit manufacturers, now has stocks of its new warm edge spacer – Thermoflex.

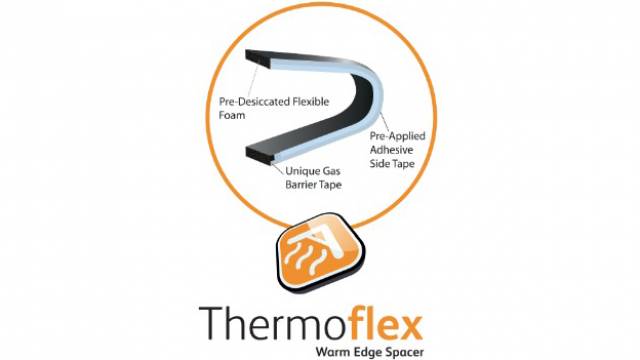

Thermoflex warm edge spacer is a pre-desiccated flexible elastomeric foam spacer system incorporating a unique gas barrier tape and pre-applied structural adhesive side tape. Thermoflex elastomeric foam rubber is a superior product in that it offers better UV stability than competitive EPDM products; it offers longevity within a sealed unit without blistering or cracking; and there are no volatiles within the product. Thermoflex rubber also has a lower thermal conductivity value than EPDM.

Thermoseal Group’s managing director, Gwain Paterson says: “We are extremely proud to officially launch our new flexible spacer system, Thermoflex. It has been a huge learning curve to develop a complex rubber spacer system and much of our machinery is bespoke so we’ve taken our time to ensure that we have perfected a premium product. The rubber is pre-desiccated and compounded in-house to give us full control of the content and quality of the ingredients from initial mixture of the product. We then control the processing, packaging and final distribution. Thermoflex is fully tested to EN1279 and EN2190-0 standards and has been through long-term trials with some of our key customers who have given us excellent feedback in developing the product for the wider market. Resultantly, Thermoflex is superior product that works on all current sealed unit manufacturing equipment that is suitable for foam spacer systems.”

“In developing our Thermobar and Thermoflex spacer systems, we has invested over GBP 2 million in our own innovation centre and equipment dedicated to research, development and manufacturing of our products. It is the support of this innovation centre and the stringent quality control procedures that we have put in place which gives me the pride and confidence that our spacer bars are superior products. We have now increased our production rate and have ample stocks of all sizes of Thermoflex; we aim to supply customers within three days or less via our own fleet of vehicles.”

Thermoflex is available in black in sizes from 6mm to 20mm. Additional colours will available shortly, as well as a 4mm profile heritage range in widths 4mm, 6mm and 8mm.