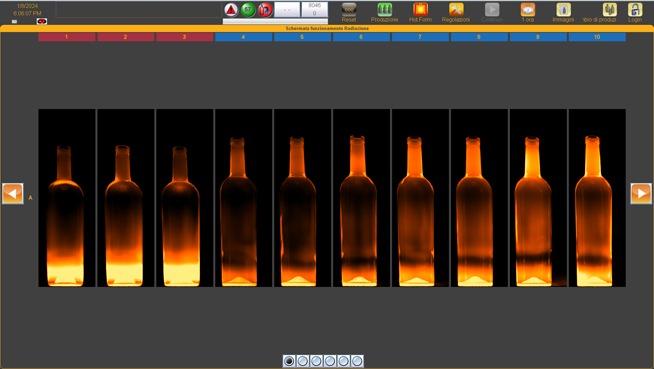

With more than 10 years of experience at the hot end, Tiama is now considered as a major supplier of hot end monitoring solutions. The company has launched in 2014 a full range of sensors dedicated to the hot end area in addition to its cold end products historically provided. Today, the Tiama HOT systems range consists of four sensors located in different areas around the IS machine from the gob with the Tiama HOT mass 2, to the exit of the IS machine with the Tiama HOT eye, the Tiama HOT form and the Tiama HOT move.

Since the launch of these products, several developments have been made and implemented on the Tiama HOT eye and the Tiama HOT form such as the integration of the Tiama HOT move features into the Tiama HOT eye software.

Many production lines are now equipped with these systems across the world. And, in order to be fully compatible with all the production lines, Tiama has recently developed the multi-product management on the Tiama HOT eye, Tiama HOT form and Tiama HOT move.

All Tiama’s systems help to monitor and improve the glass process. Defects are detected at the hot end, allowing operators to perform quick corrective actions on the IS machine without waiting for cold end feedback. And thanks to the glass distribution analysis provided by the Tiama HOT form, defects creation can even be anticipated. In addition, ware handling is also improved with the Tiama HOT move. Jams on the production line are considerably reduced and pushers’ settings can be optimized thanks to the information provided by the sensor.

With this last development, mixed production lines now benefit from all the features available on the hot end sensors and the Tiama HOT systems range continues to grow with new features.