Vetropack Group has commissioned a new melting furnace as well as two servo-driven glass forming machines and another glass forming machine at its Czech site in Kyjov. The process of heating up the modernised melting furnace commenced on January 15.

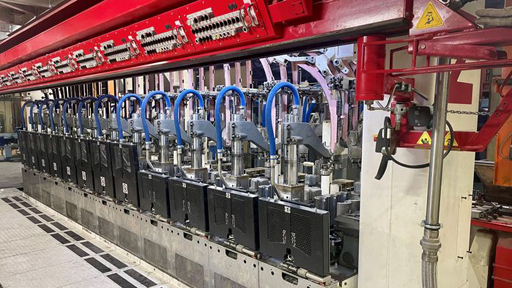

The retrofitted, state-of-the-art melting furnace is designed for producing coloured glass. It offers a higher capacity in comparison to the previous furnace. Additionally, two servo-driven NIS glass forming machines as well as an AIS glass machine have been successfully launched at the site.

Vetropack had initially scheduled the commissioning of the furnace and the two NIS machines for autumn of 2023. “Due to inflation and uncertainty in the European market, Vetropack opted to postpone the start of production to the beginning of 2024, as the company announced in October.”

The Czech site of Vetropack Moravia Glass celebrated its 140th anniversary in 2023. It is one of the key glass packaging suppliers for Central Europe, symbolising the successful outcomes of integrating tradition with modern technologies. With the latest reconstruction work, the site reaffirms its commitment to innovation and sustainability in a dynamic market environment.

“The path to increased sales lies in more modern and efficient production facilities,” said Boris Sluka, Managing Director of Vetropack’s Business Unit Czech Republic and Slovakia. “While the market situation remains challenging, our proactive approach in seeking new customers has enabled us to, at least partially, supplement our production capacity.”

The two NIS glass forming machines represent a significant milestone for Vetropack. “Servo technology offers numerous advantages, with the NIS machine standing out for its extremely accurate control of the glass-forming process. As one of the most flexible and high-performing machines available in today’s market, it substantially lowers energy consumption, improving efficiency and capacity,” said Boris Sluka. “Moreover, the machine improves the working environment by minimising noise and enhancing operator safety through reduced human interaction when compared to pneumatic devices. We take pride in inaugurating these cutting-edge machines in Kyjov.”