Glass container inspection processes over the last few decades have been characterised by human manpower and optical inspection technologies. The defect identification process has greatly improved thanks to innovation in electronic and optical devices, but some processes still remain unviable.

|  |

Today, systems perform well even when it comes to identifying small defects, but sometimes performance can be affected by false positives. Glass manufacturers rely more and more on improving production and identifying optimal defects which is by extension, better for the environment. Production optimisation ultimately generates less pollution per market product tonne delivered. This article proposes an artificial intelligence approach to optimise standard glass container inspection methods.

FEWER FALSE POSITIVES

Thanks to AI developements carried out by Video Systems starting in 2003, colour image analysis in 2018 and the increasing adoption of research, technology and market feedback, we have seen a notable reduction in false positives and our Imago line systems are better able to identify specific hard-to-detect defects.

Considering that quality control in hollow glass production is key especially as the final product (bottles, tableware, containers) are made for high quality demand markets such as pharmaceutical, food and beverage, quality control systems technology has had to keep up.

All non-conforming containers are removed from the production chain and used as recycled glass (scrap). At the exit of the line, the products are finally packed and palletised for subsequent delivery to final customers.

AUTOMATED SYSTEMS

While people can be very skilled in the control task, they can’t guarantee the same reliability and speed required by current production cycles. For this reason automated systems for the quality control of glass containers have been introduced on production lines in past years.

The purpose of every hollow glass maker is to produce more containers with best quality and lowest cost.

For this reason the quality control industry system is working every day to improve inspections with two main goals:

- increase the capability of systems to identify defects

- reduce the false positives on containers inspection

Video Systems Imago line products today are powered with many AI engines dedicated to various defects.

SIDEWALL QUALITY CONTROL

In the case of stones identification the use of Artificial Intelligence technology can significantly reduce false positives. This approach also cut down on machine setup time thanks to reduced parameters and self-tailoring. Thanks to AI, the system is also able to automatically generate receipts on new containers based on machine experience and manage different shaped containers at the same time.

Video Systems Imago Omnia sidewall machine thanks to AI-engine is now able to reduce false positives effect to zero point five per cent.

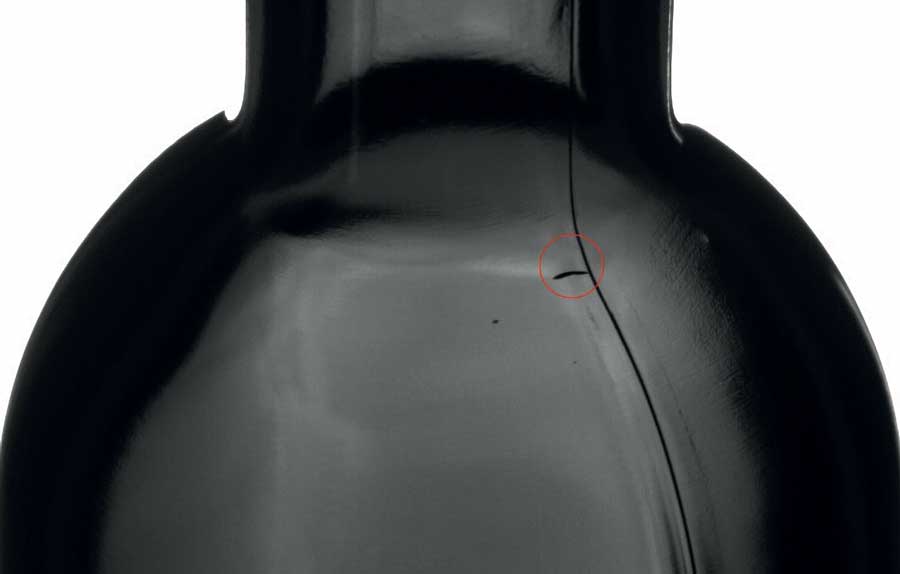

One of the biggest advantages of the AI engine approach in this case, is the system’s ability to identify real stress defects rather than detecting reflections on the container surface, which usually is an issue with high density containers such as Champagne bottles.

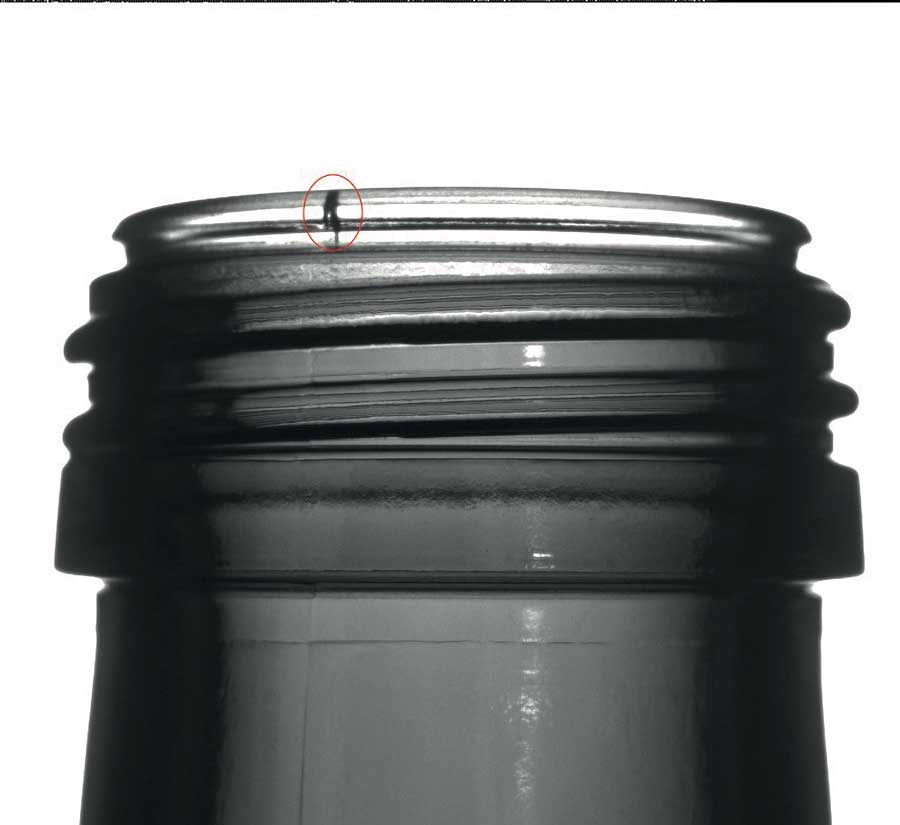

SHOULDER AND FINISH CRACKS

In order to identify a crack with standard carousel machines, the operator needs to setup a light emitter and receiver to be perfectly aligned with the reflection angle, which means that if the crack is different, the machine needs a new alignment.

Linea system is a contactless solution for these type of defects and thanks to its AI engine the operator doesn’t need to setup light emitter and receiver, since they only need to select the ROI of analysis and other parameters like minimum defect size.

In the case of special containers such as perfume bottles, the tailor-made AI engine helped the final application detect very slight defects such as small base cracks (Fig. 16) or broken corners.

CONCLUSION AND OUTCOME

Hollow glass quality control is an increasingly important requirement for producers due to the rising demand for quality by the end.

For many years the glass inspection task has been performed by hand without the reliability and speed required by current production cycles.

Nowadays almost all production lines provide automated systems for the quality control of glass containers. These systems use vision systems that can analyse bottles and identify defective bottles. They use classic algorithms to detect defects and therefore need to set a high number of parameters. Some of these methods also need the defective sample in order to prepare the recipe for analysis.

The Video Systems approach is focused on an AI based solution. Over the last year we are working on new tailor-made solutions that apply robotics, AI and machine vision technologies to supply future solutions to market research that is supported by EU in APICUS and ZDMP H2020 projects (www.zdmp.eu).

Video Systems Srl

www.videosystems.it