With over 250 pressing, blowing, spinning, handling, and fire polishing solutions up and running all over the world, Waltec works closely with its customers, taking business to the next level, challenging clients to build together better manufacturing processes which, in turn, contribute to a more sustainable industry footprint.

|  |

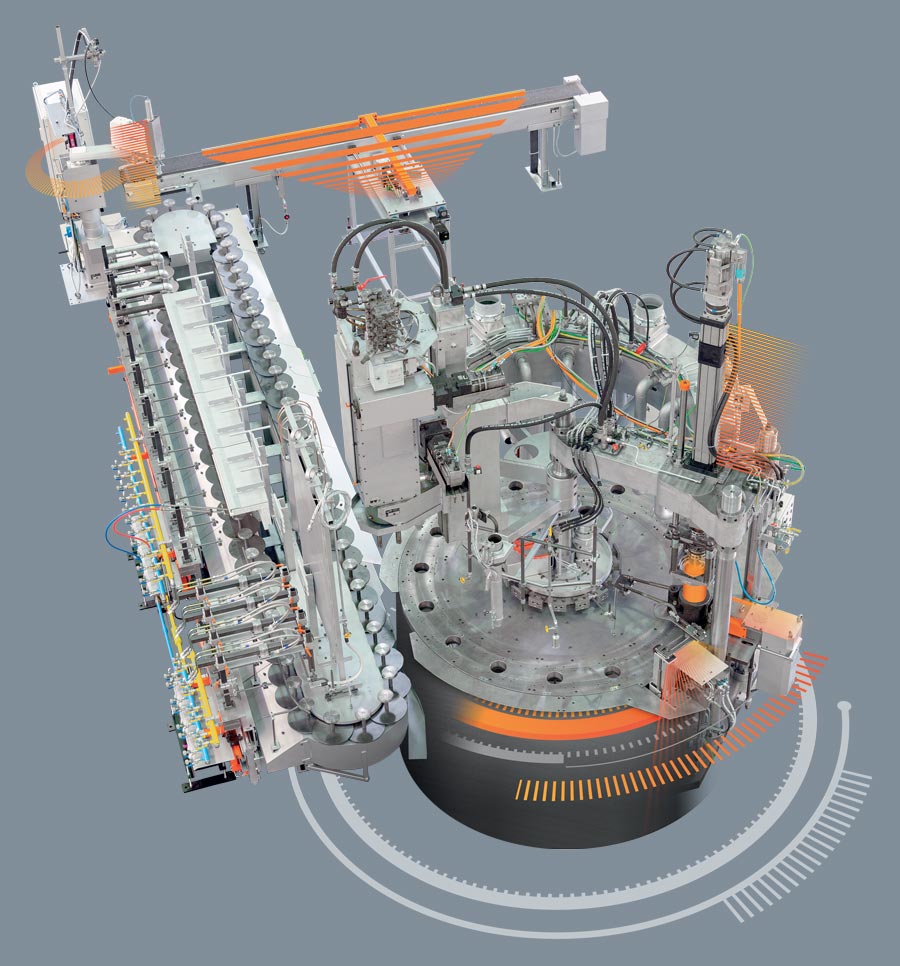

Waltec is a leading manufacturer of fully automated and electronically controlled production lines – from feeder up to annealing lehr. Over time, Waltec has successfully migrated its in-house designed and manufactured state-of-the-art pressing, blowing, spinning, handling, and fire polishing solutions into more than 250 manufacturing locations around the globe.

Transforming hot-end operations through improved resource efficiency and reduced energy consumption is their key challenge. Waltec’s team of dedicated industry experts is there to make this happen.

WALTEC’S VALUES: RELIABLE BY TRADITION AND DRIVEN BY INNOVATION

Waltec practices the highest standards for health and safety and integrates this into their innovative production lines, components, and services. The company fully recognizes their broader responsibility towards its employees and society and even better, acts accordingly. Long term relationships based on trust and performance form the backbone of its successful long-lasting business model.

Waltec stated: “Sharing our ongoing and exciting innovation path with you and go together the extra mile to create a better forming process is our passion. Our company offers continuous learning and improvement. Apprenticeship and permanent education is part of our DNA. Young people get the chance to develop themselves through an integrated, practical on the job training concept. We believe that only motivated and skilled employees are capable of delivering top performance to our customers.”

“We are creators of innovative glass manufacturing technology, we design sustainable production processes, we build cost-effective production lines and components targeting the optimization of your hot-end process.” Dipl-Ing. Britta Höfer, Waltec owner and managing director.

“Our decisions are guided by the principle that we should empower our people so that they can transfer our world-class technology knowledge into solutions that help our friends in the glass industry to cope with today’s complex challenges.”

The family tradition and heritage safeguards these values across the globe and that’s why Waltec is proudly saying: “reliable by tradition and driven by innovation”.

TOWARDS A BETTER HOT-END FORMING PROCESS – SHARING TECHNOLOGY AND EXPERIENCE

Creating a better hot-end press-process empowered by the latest available machine, process, and software data technology has inspired the Waltec team to develop a new range of so-called E-SERVO performance components. Transforming and upgrading the sustainability footprint of older in-market press machines is now possible:

1. Lower energy consumption

2. Less cost

3. Higher output

4. Sustainability inside

Waltec presented this innovation to the global glass industry via a special webinar during glasstec virtual.

PROCESS DESIGN AND MACHINE DEVELOPMENT

“Each customer inquiry is, for Waltec, unique and will always be handled by a multi-disciplinary project team of Waltec specialists looking for the best possible solution. Teamplay guarantees the best possible customer satisfaction,” confirms Waltec’s commercial director, Herman Green.

INDUSTRY 4.0 – BIG DATA ANALYTICS

Process optimization and the use of data analytics is nowadays a must to stay ahead of competition. Contemporary software solutions analyzing and optimizing data and efficiencies are embedded in self-engineered artificial intelligence. Waltec delivers tailor-made processes and machine designs to comply with Industry 4.0 standards and even far beyond.

QUALITY THROUGH IN-HOUSE MANUFACTURING

All activities, from design to manufacturing, up to customer delivery, and the start of operations, are executed by a qualified team of experts and specialists. Waltec offers a one-stop customer approach. The risk of third-party failure is eliminated and the highest quality is guaranteed according to the companies management team.

24/7 AFTER-SALES SERVICE AND PRODUCTION SUPPORT

Once in operation, the service team is always there to help. The team operates a 24/7 service model and herewith helping customers around the clock to increase output, reduce downtime and ensure continuity in operations. Recently Waltec successfully started a new innovative service named remote commissioning. This service made it possible to start up a brand new production line in China without the service team had to be on site. Waltec’s operations director, Mr. Rainer Wagner: “Online troubleshooting, as well as direct communication with our service experts, is highly appreciated by all of our customers.“

Waltec Maschinen GmbH

www.waltec.de